Composite Materials

Composite Materials

Description

Composite material design is the process of creating and analyzing structures that combine different materials to achieve desired properties. Typical composite components include carbon fiber, glass fiber, ceramics, and metals.

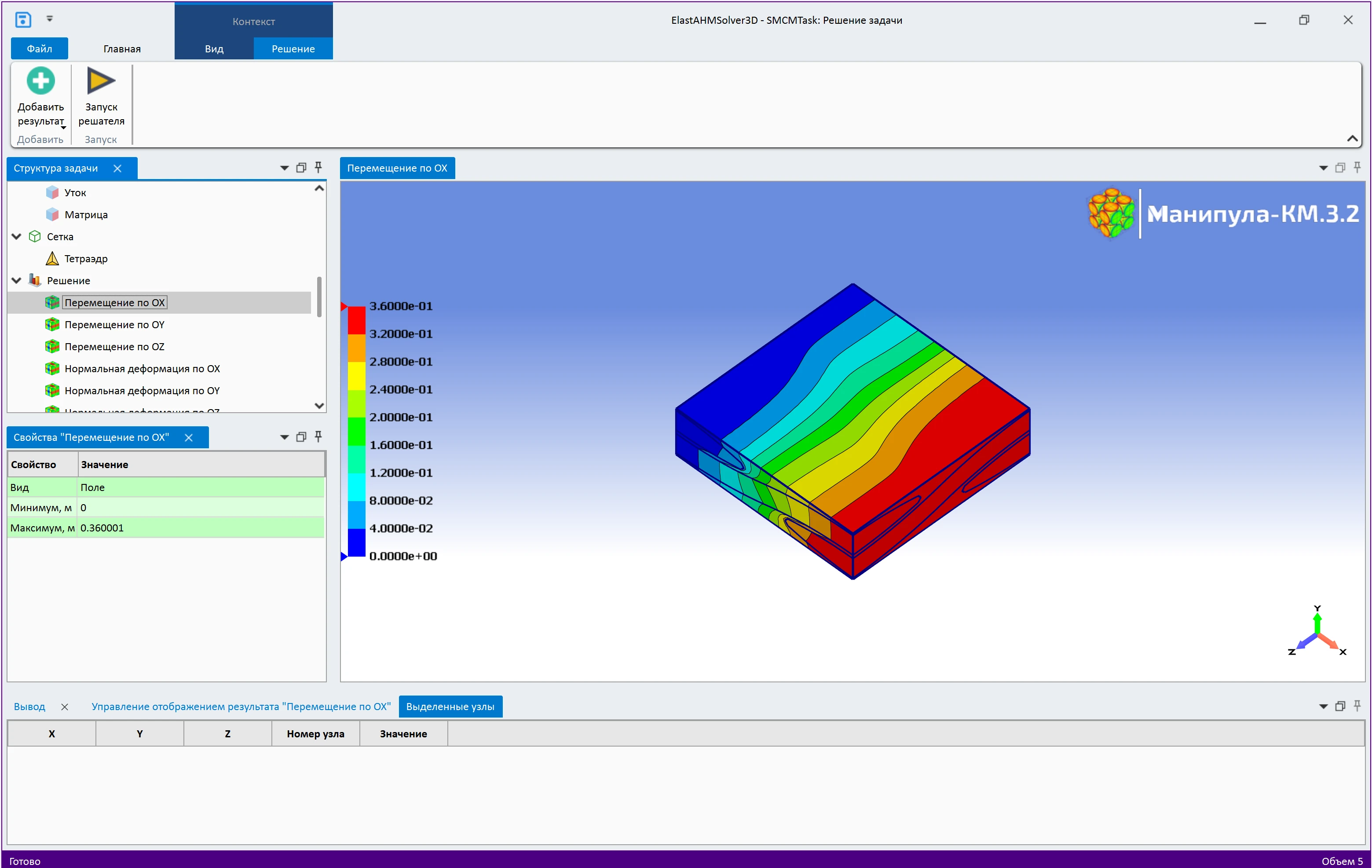

The Manipula/SMCM 4.0 software package provides tools for modeling key manufacturing processes of composite structures:

- placement of fillers (fabrics, tapes, etc.) on curved surfaces with draping considerations; creation of fabric cuts and development patterns;

- impregnation of reinforcing frames with liquid binder (using infusion, RTM, and other methods);

- curing of composite structures;

- technological stresses and distortions in composite structures during curing.

Capabilities

-

Composite structure framework formation:

- fabric placement;

- yarn deformation during placement.

-

Impregnation of polymer composite materials (PCM) with binder:

- RTM process.

-

Curing of polymer composite materials (PCM):

- curing of 3D structures.

-

Technological stresses and distortions in polymer composite materials (PCM):

- technological stresses in PCM;

- technological stresses in PCM after removal from tooling;

- warping of composite materials during cooling;

- warping of composite materials during curing.