Macro-Analysis

Description

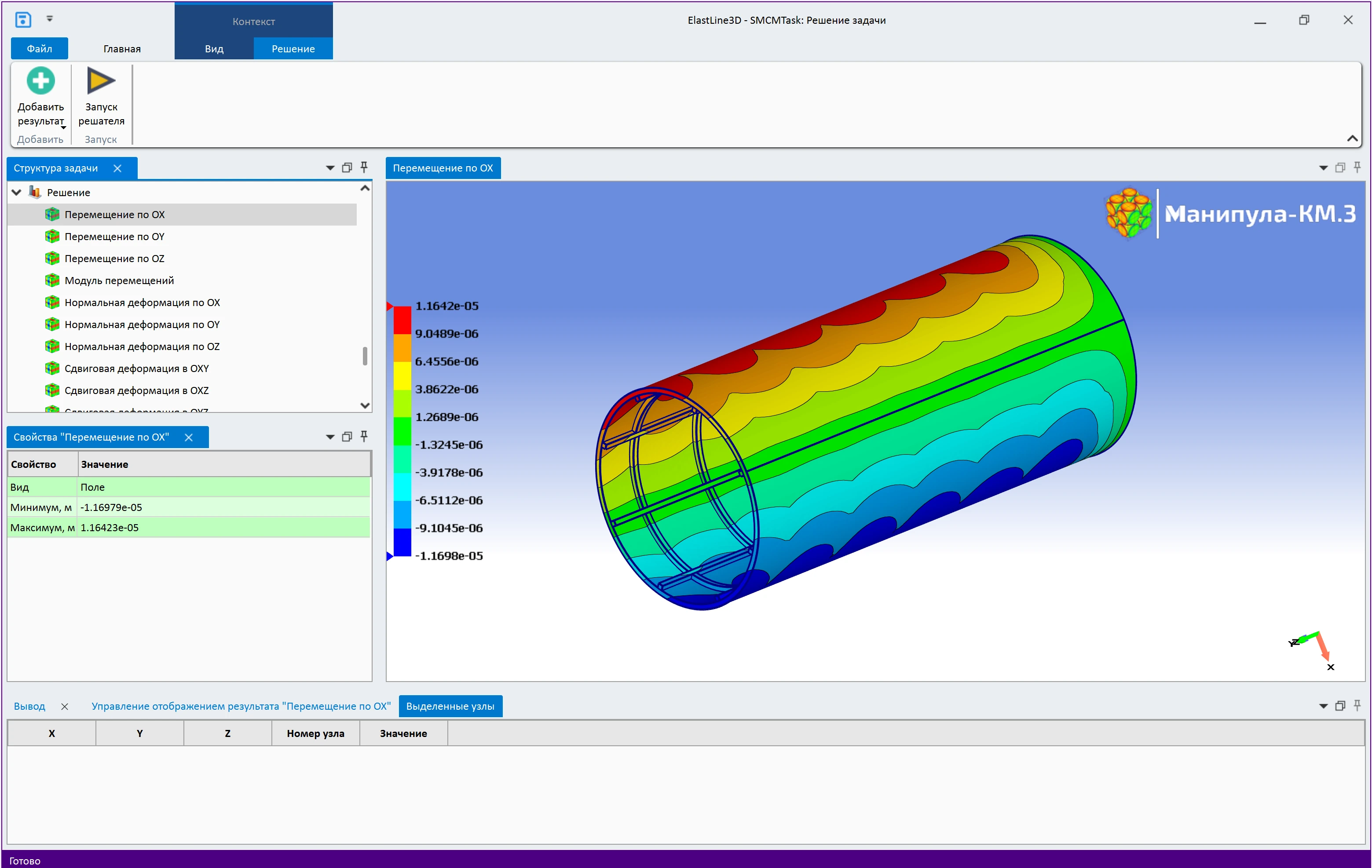

Macro-analysis in the «Manipula» software package refers to methods for modeling the behavior of materials and structures at the macroscopic level. Built‑in solvers operate with global characteristics: stress, strain, and displacement. This method is used to solve problems in solid mechanics under static, dynamic, and thermal loads.

Manipula/SMCM 4.0 implements a modular approach to calculating composite structures—both 3D solid and 2D shell types. The following types of problems are supported:

- quasi‑static mechanics;

- heat conduction;

- thermoelasticity (coupled problems);

- modal analysis;

- forced harmonic vibrations;

- stability and thermal stability.

All macro-analysis modules account for the complex anisotropy of materials when calculating composite structures.

Capabilities

-

Quasi‑static problems in elasticity theory:

- linear elasticity;

- linear elasticity with process effects;

- thermoelasticity.

-

Modal analysis:

- natural vibrations;

- natural vibrations with pre‑stress (PN);

- natural vibrations with process effects;

- natural vibrations with damping;

- natural vibrations with both process effects and damping.

-

Dynamic problems in viscoelasticity theory:

- forced harmonic vibrations of a viscoelastic medium.

-

Stability theory problems:

- stability;

- nonlinear stability;

- thermal stability;

- stability under combined loading;

- stability with process effects.

-

Quasi‑static problems in plasticity theory:

- deformation plasticity;

- deformation plasticity with process effects;

- deformation plasticity with strength criteria;

- deformation plasticity with fracture;

- deformation plasticity with both fracture and process effects.

-

Quasi‑static problems in shell theory:

- linear elasticity of shells;

- linear elasticity of shells with process effects;

- shell strength.

-

Heat conduction problems:

- steady‑state heat conduction;

- transient heat conduction;

- transient heat conduction under high temperatures (VT).